Willkommen zur German Website

Wir haben festgestellt, dass Sie möglicherweise die Global Seite bevorzugen. Bitte verwenden Sie die obige Auswahl, um Ihre Sprache bei Bedarf zu ändern.

Go to Global

- Produkte

- Lösungen

- Support

- Services

- Über uns

Willkommen zur German Website

Wir haben festgestellt, dass Sie möglicherweise die Global Seite bevorzugen. Bitte verwenden Sie die obige Auswahl, um Ihre Sprache bei Bedarf zu ändern.

Performance enhancing precision temperature control and power control for semiconductor equipment and processes

Download BrochureWhy is precise control critical for semiconductor fabs >

Helping maximize semiconductor fab efficiency >

Operational resilience in semiconductor fabrication >

Sustainability for semiconductor manufacturing >

Explore our semiconductor application expertise >

Custom solutions for OEMs >

Service Level Agreements >

Whether replacing an existing product or building a new process, the design of the EPack compact SCR power controller has been carefully designed with Semiconductor fabrication processes in mind.

Discover more >

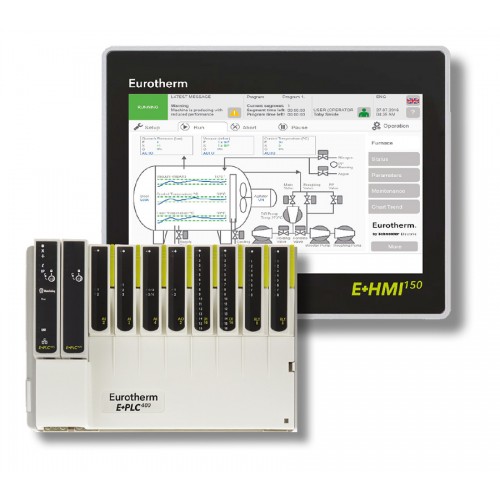

Advanced control, data management and visualization in a modular platform solution.

Discover more >Learn more about semiconductor industry best practices and how Eurotherm can help improve your process.