Willkommen zur German Website

Wir haben festgestellt, dass Sie möglicherweise die Global Seite bevorzugen. Bitte verwenden Sie die obige Auswahl, um Ihre Sprache bei Bedarf zu ändern.

Go to Global

- Produkte

- Lösungen

- Support

- Services

- Über uns

Willkommen zur German Website

Wir haben festgestellt, dass Sie möglicherweise die Global Seite bevorzugen. Bitte verwenden Sie die obige Auswahl, um Ihre Sprache bei Bedarf zu ändern.

Eurotherm Customer FIRST Warehouse Mapping Service

Peace of mind that your regulatory storage requirements are met

Eurotherm Customer FIRST Warehouse Mapping Service delivers the required evidence to demonstrate that environmentally sensitive products have been stored in accordance with Good Manufacturing and Distribution Practices (GMPs and GDPs).

Our turnkey service includes:

Regulators such as the Medicines and Healthcare products Regulatory Agency (MHRA) increasingly require temperature and humidity profiles of storage and distribution warehouses to demonstrate that environmentally sensitive products have been maintained within a GMP or GDP compliant environment.

It is important to consider the risks that can affect product quality before making the necessary mitigation and validation plans. If procedures are not well understood, audit failures can occur which not only result in waste product but also have a negative impact on a company’s reputation.

Carrying out successful warehouse mapping involves a process of steps which can require trained individuals with expert knowledge in certain areas, such as GMPs, GDPs, Data Acquisition and Analytics, Storage Methods and HVAC (Heating, Ventilation and Air Conditioning).

Eurotherm field services team have a wealth of knowledge and expertise in environmental monitoring and temperature uniformity surveys. Supplied as a service or as part of a Customer FIRST Service Level Agreement program, our knowledgeable team can carry out the comprehensive set of tasks needed to help you prove that your environmentally sensitive products have been stored within their specified limits, to satisfy regulatory requirements.

To minimize the time and regulatory concerns associated with in-house validation, consider handing the task to Eurotherm Service Team

We will provide and locate the high stability temperature and humidity sensors and calibrated equipment for data logging, and define and carry out the mapping and validation procedure. Sensors will be placed in a defined pattern and monitored at stated intervals for a specified length of time to take into account different periods of operations in the warehouse, and the specifications for the type of products being stored. Acceptable limits for temperature and humidity excursions will also be stated and reported.

Eurotherm engineers work with you to create your validation plan in order to define the equipment, plant and personnel protocol needed to maintain a GMP/GDP environment. As experts in measurement and environmental monitoring they will be able to offer advice on the validation process as well as provide the equipment required.

Our background in Environmental Monitoring Systems provides the expertise needed to define areas where product quality may be at risk from temperature and humidity deviations, such as where HVAC systems or fans may cause variations or where temperature gradients can occur due to storage warehouse layout or HVAC system design.

We provide:

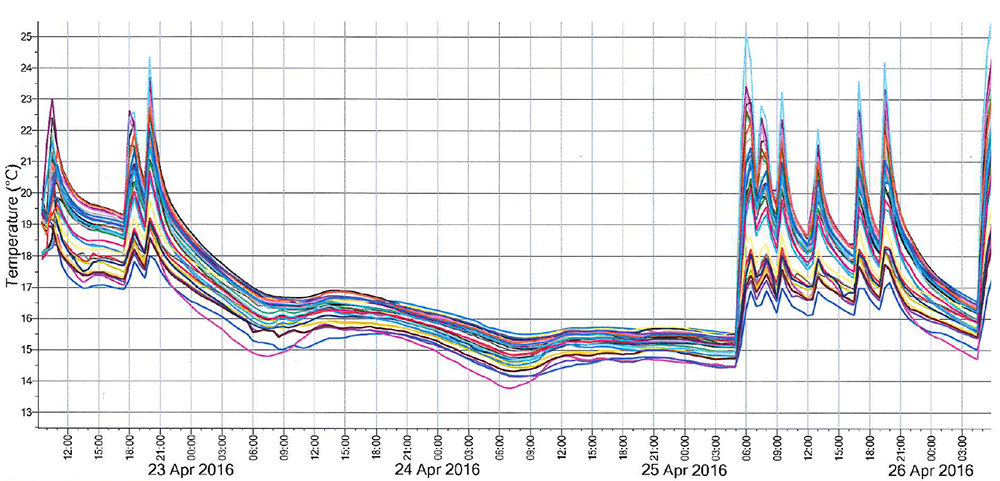

Our comprehensive report will provide easily readable graphical and tabular results of your warehouse data with time and dates as well as other requested calculated values such as min, max and average. Information such as instrument settings, calibration certification and pass/fail information are also included for review and approval by your responsible quality personnel.

Where unacceptable extremes of temperature or humidity are identified, we will help and advise on changes to be made to storage or HVAC systems as well as documenting the modifications and updating the validation procedure.

For pharmaceutical manufacturers, our comprehensive report enables them to easily demonstrate to regulatory bodies, for example the MHRA (Medicines and Healthcare products Regulatory Agency), that the requirements of standards and guidelines such as European GDP guidelines 2013/C 343/01 and 2015/C 95/01, have been met.

For warehouses that require continuous monitoring to conform to GMPs, Eurotherm also offer fully engineered and validated Environmental Monitoring Systems (EMS).

Subsequent mapping activities can be scheduled within a Eurotherm Service Level Agreement to occur on an agreed frequency.