Need help choosing the right product?

Our tool will match the best product to your needs

Launch product selectorWelcome to the Global Website

We have detected that you may prefer the Global site. Please use the language dropdown above to change your selection if required.

This is a series of processes where the materials at the atomic or molecular level are deposited on the surface of a wafer as one of multiple thin layers that contain electrical properties.

Eurotherm precision temperature and power control offers precise, uniform and stable temperature control, reducing the risk of these common and detrimental process effects. This improves yield and quality.

The wafer temperature is controlled using a cascade configuration where the wafer temperature uses the inner loop, and the heating element temperature uses the outer loop.

Increasing demand for more powerful devices in smaller sizes (for example in computation, data storage, communication, energy storage, and sensing technologies) has resulted in the development of semiconductor manufacturing tools for more precise control of thin films. Critical film layers in today’s transistors are only a few atoms thick. Atomic Layer Deposition (ALD), also known as Atomic Layer Epitaxy (ALE), is a vapor-phase deposition technique used to grow these ultrathin films.

Chemical reactions are used to grow films one atomic layer at a time. By managing the cycle stages, it is possible to achieve precise control of the quantity and composition of the layers. Uniform coverage is possible on any topology or 3D structure. These chemical reactions are thermally driven, most frequently by heating a substrate, and can be further enhanced during the gas-phase by applying plasma assistance during the deposition process.

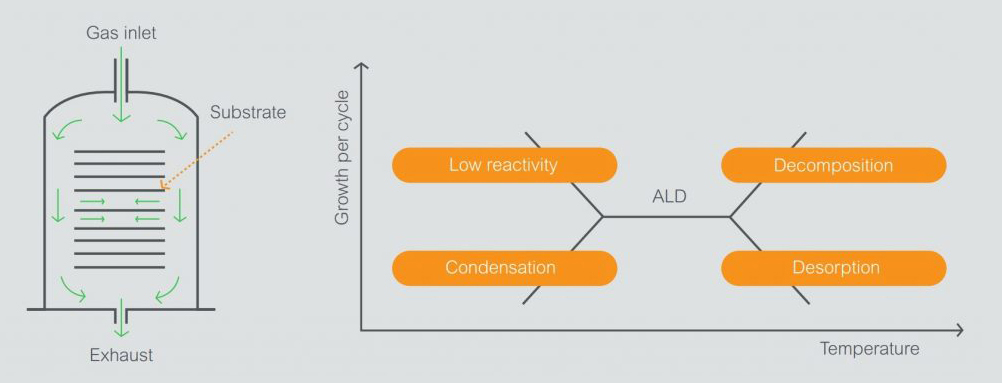

Self-limiting uniform growth can only be achieved within an ideal temperature range. If outside this, the ALD process could be impaired by one of the detrimental effects shown in the diagram below.

Atmospheric contamination in the chamber can lead to undesirable growth defects in the film layers, impacting the surface chemistry and ultimately reducing the performance characteristics. Controlling the environment within the chamber is critical to avoid this contamination.

All chamber temperatures are monitored outside the chamber. Temperature control is generally provided via precise control of the energy input.

Temperature control of the ALD process is key to prevent the following detrimental effects:

Growth control becomes even more important on large substrates (large wafers etc.) to achieve uniformity of the film.

An ALD reactor heats the samples to the desired deposition temperature. Pulses of precursors and co-reactants are injected into the reactor chamber. An inert gas is typically used to purge the reactor between the steps. Filling and purging of the reactor chamber should be efficiently controlled to achieve reasonable cycle times.

The timing of individual cycle steps needs to be accurately controlled.

A typical cycle consists of four steps:

The EtherCAT Technology Group ETG (www.ethercat.org) was created to keep EtherCAT technology open for all users. SEMI™ (formerly Semiconductor Equipment and Materials International) has accepted EtherCAT as a communication standard (E54.20) for the semiconductor industry.

Product Selector

Our tool will match the best product to your needs

Launch product selectorContact Us