Need help choosing the right product?

Our tool will match the best product to your needs

Launch product selectorWelcome to the Global Website

We have detected that you may prefer the Global site. Please use the language dropdown above to change your selection if required.

With the automotive industry demanding more and more stringent tolerances and introducing more complex forms and shapes, the production process of automotive glass panels has become extremely complex.

Resulting, for example in a Tunnel furnace, having hundreds of sub zones, requiring precise and complex temperature control running multiple recipes to allow maximum production flexibility. Resistive elements as well as medium wave infra red heaters have to be controlled to very tight parameters whilst maximizing energy efficiency.

Eurotherm temperature control, power control and supervisory systems for windscreen forming are in operation around the world and provide:

Eurotherm has always been present and successful in power glass applications such as:

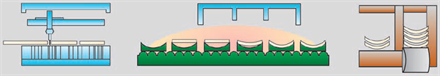

The principle of windscreen forming is that the flat windscreen is going through a tunnel furnace on a very precise form. There is one type of form per type of windscreen. When at the right temperature, the soft glass will take accurately the form banding by gravity.

The first part of the furnace is the pre-heating zone, temperature controlled. Second part is the forming zone with a precise electrical power control. Heating elements are metallic resistors, medium wave infra-red, with a low temperature coefficient. Heat transfer to the windscreen is a combination of air heating and infra-red emission.

The quality and precision of the windscreen banding is given by the accuracy of the pre-heating zone temperature control and the accuracy of forming zone power control.

For such furnaces, the number of zones can be very high, 100 to 300 zones. Present tendency is to increase the number of zones to improve precision of banding and to manufacture more complicated and various windscreen shapes. Total power of such furnaces ranges from several hundred kW to several MW.

Architecture of installation

The architecture of the installation in terms of electrical control as follows:

Through communication link (Modbus or Profibus depending on type of PLC). All EPower parameters are available (read and write) on the supervisory system: power set point, load output power, status word/alarms.

On the furnace forming part, during process time each windscreen stays in a heating zone; its next working set point, for the next heating zone it will move into, is loaded in each EPower channel. When all the windscreens reach their next heating zone, a single command through the communication link will transfer all pre-loaded set points for each zone as an active set point, this being done in a few milliseconds.

Product Selector

Our tool will match the best product to your needs

Launch product selectorContact Us