Need help choosing the right product?

Our tool will match the best product to your needs

Launch product selectorWelcome to the United Kingdom Website

We have detected that you may prefer the Global site. Please use the language dropdown above to change your selection if required.

Managing low and high temperatures in Semiconductor PECVD processing for solar cell fabrication

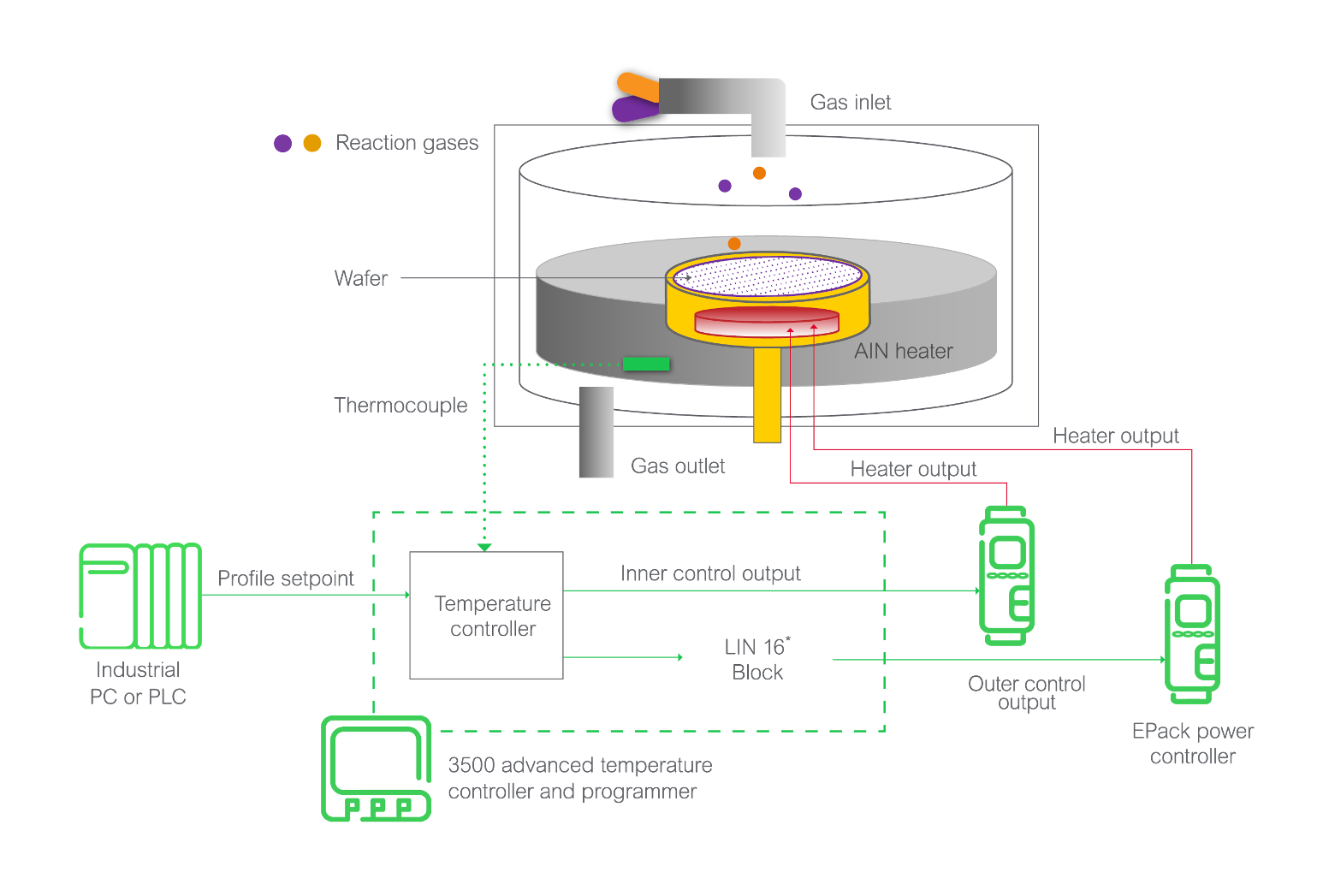

The process we describe here is specifically the diffusion and plasma-enhanced chemical vapor deposition (PECVD) for solar cell fabrication. PECVD is a chemical vapor deposition process to grow and deposit ultra-thin films onto the wafer from a gas state.

Product Selector

Our tool will match the best product to your needs

Launch product selectorContact Us