Need help choosing the right product?

Our tool will match the best product to your needs

Launch product selectorWelcome to the USA Website

We have detected that you may prefer the Global site. Please use the language dropdown above to change your selection if required.

Whether it’s for excellence in control, ease of use or its flexible and creative solutions, the 3000 Series can be used in many applications to solve problems and save time and money.

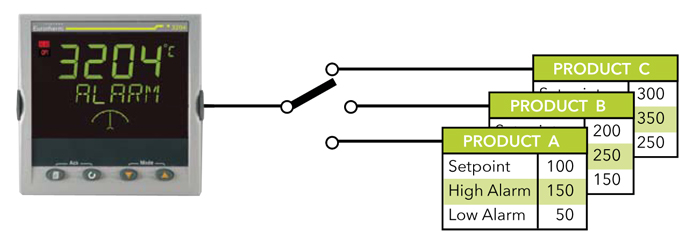

The 3000 recipe function is unique in a controller of this class. Recipes can be stored under a user-defined name to recall a number of parameter settings. These settings may include operating variables or configuration parameters, providing a very powerful means of altering the set up of a controller in a single operation. Recipes may be recalled either from the HMI, over the communications link, or using digital inputs.

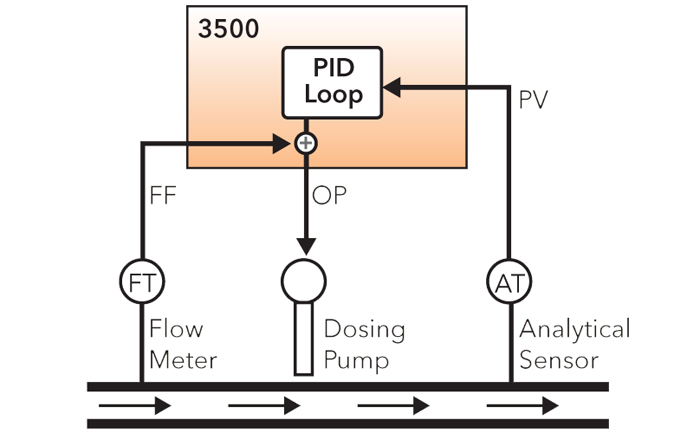

Feedforward is a control technique used to compensate for future disturbances or process changes. It provides an offset on the controller PID calculation to ensure that corrective action is taken to prevent the measured PV being disturbed. A typical application is additive dosing. By measuring the flow rate upstream from the dosing pump it is possible to use the feedforward feature of the 3500 to achieve an output proportional to the fluid flow rate. This means that the dosing rate immediately tracks any changes in flow rate and so prevents any possibility of dangerous over dosing.

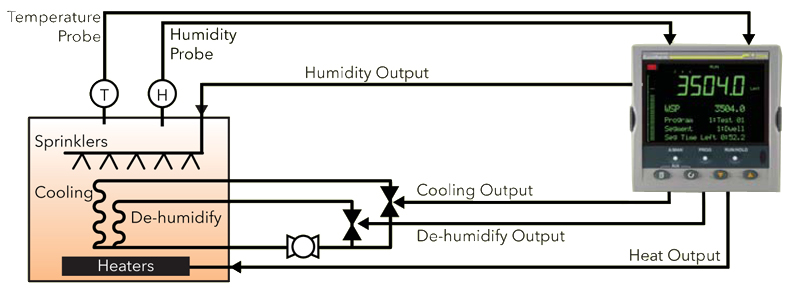

Many applications need to vary temperature, or other process values, with time. Thesetpoint is varied by using a setpoint program. The program is stored as a series of ‘ramp’ and ‘dwell’ segments. All 3000 Series controllers provide this feature. The 3200 has an extremely easy to use 8 segment programmer for simple applications while the 3500 has a very flexible dual channel programmer with storage for 50 programs. The 3500 is ideal for furnace, environmental chamber and autoclave applications that require greater flexibility.

The Dual Loop capability in the 3500 makes it ideal for controlling interactive processes such as those found in carburising furnaces, environmental chambers, autoclaves and fermenters. All of these applications require control and often setpoint programming of two variables. By using the advanced maths and logic functions within the 3500, intelligent control strategies can be created to compensate for interactive effects between variables and maintain them at setpoint.

The zirconia block calculates carbon potential, oxygen concentration and dew point based on the temperature and probe mV measurements from a zirconia oxygen probe. Probe burn-off sequence and diagnostic alarms are also available to help extend the life of the probe and predict impending probe failure while minimising downtime and rework. This feature enables the 3500 to be used to control carbon potential in an atmosphere furnace, an inert atmosphere in a sintering furnace and dewpoint in an endothermic generator.

The simple timer in the 3200 may be used to control batch operations, eg. food ovens, sterilisers, fryers. Ideal for any application requiring a single dwell at the end of either a controlled ramp or natural approach to setpoint without the need for an additional timing device.

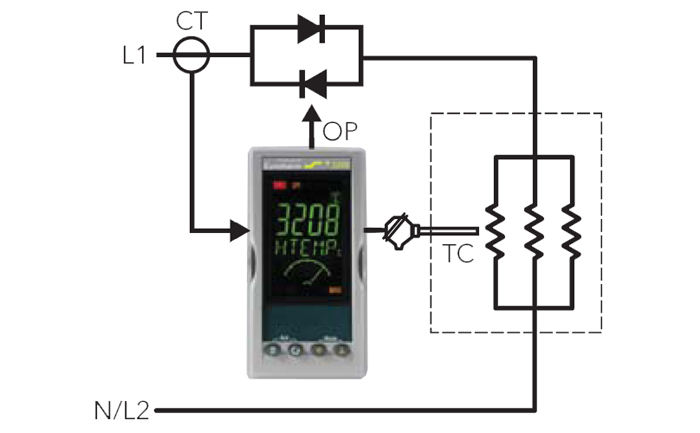

A current transformer input in the 3200 measures the current switched through the load. The measurement is filtered so that the on current and off currents can be separated. From this it is possible to diagnose several load faults including partial load failure, over current and an SSR fault. Typical applications include plastic extrusion, laboratory ovens and other applications where early indication of heater failure can save energy and rework costs.

The HMI on 3000 Series controllers are customisable to show plant information in the format that is most useful for the operator. Customisable scrolling text can indicate event and alarm conditions, to trigger another function, or instruct an operator of the current state of the process. The 3500 has additional facilities to enable a user to design their own user interface.

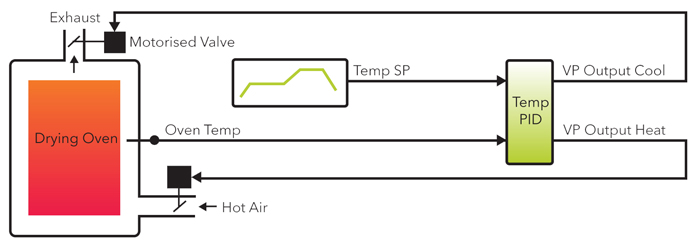

The Dual Valve Positioning (VP) feature on the 3500 allows two motorised valves to be modulated from one controller. Typically one valve would actuate a burner or hot air inlet and the other a cooling damper. This feature removes the need to interface the controller via external positioners. The VP feature can be used with or without a feedback potentiometer and can also be used with PID in either control channel to provide control strategies such as PID Heat/VP Cool.

In all 3000 Series controllers it is possible to use the Modbus RTU communication link to send a value, (often setpoint) from one controller to a network of slave devices – providing the economical creation of multi-zone temperature control solutions.

User calibration can be performed in all 3000 Series controllers. The 3200 provides a simple two point calibration on its input and the 3500 has a comprehensive set of transducer scaling options that make it ideal for melt pressure, load cell or comparison type calibrations.

Product Selector

Our tool will match the best product to your needs

Launch product selectorContact Us